How much to charge for 3D printing? An Example

You bought a hobbyist 3D printer and struggled to make it run properly for quite some time, but now you have mastered it and want to make some money from this endeavor? Or did you take up 3D printing with the only goal of making it a business? It doesn’t matter.

How to price such a service can be a tricky question, but today we will give you a step-by-step guide and an example on how to figure out your pricing strategy.

We want to help you as much as possible in your 3D printing journey, so we will share with you a concrete example to make things as clear as possible. We will calculate how much you should sell this 3D Benchy (if someone would be willing to buy a Benchy anyway).

Pricing 3D prints

As with everything in business, there is no one-size-fits-all formula. You will have to keep in mind four key factors when giving quotes to customers. They are as follows:

General costing factors in 3D printing

Expenses are relatively straightforward and most of them are easy to calculate. Material and labor costs are going to be the biggest in the long run, but they can be very predictable. In terms of operation, 3D printers can be considered cheap as they don’t consume that much power and have a pretty long lifespan.

Material costs

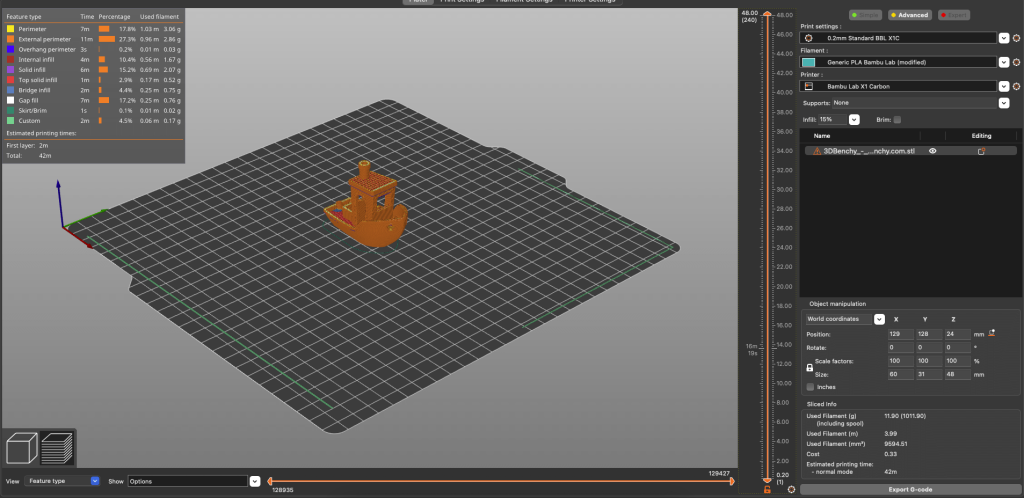

Slicers give a pretty accurate estimate of how much material a 3D print will need. It’s important to keep in mind that the weight of the 3D print fluctuates as you change the infill, number of walls/shells, etc. Some slicers, such as PrusaSlicer calculate the material costs for you. Very convenient!

The bottom line for material costs is: Material cost = filament price / filament weight (grams) * model weight (grams):

For our example: $27.99 / 1000 * 11.9 = $0.33

Keep in mind that saving from materials might not be the best strategy to increase profits. While it may benefit your bottom line in the short term, you should consider that cheaper filaments and resins have unreliable quality control and worse material properties in general. This makes dealing with them much harder and you will encounter failed prints more often. You will be much better off if you find a store that gives a discount when buying in bulk. You can’t have too much filament after all, right?

Labor costs

The highest running costs associated with 3D printing... Prepare to pay the biggest chunk of your money for manpower. Even if you are the one doing the job, you should charge a healthy hourly rate to make it worth your while. As you gain more experience, you will know exactly how much time each 3D print job will take you in terms of manual labor.

Depending on the niche and the models you are 3D printing, the time spent will vastly vary. Sometimes simply downloading a file from the internet will work right away, while other times, you might need to edit it or completely build it from scratch.

Formula: Time spent (in minutes) / 60 * hourly wage = labor costs

For our example of printing a Benchy, the manual labor involved would be no more than 5 minutes. If we want to pay ourselves $14 per hour, here is how that’s going to look like: 5 / 60 * $14 = $1.17

3D printer operation costs

Most people immediately think about the electricity bill but that’s not where your attention should be. 3D printers don’t consume that much power. While the bed is heating up, the power consumption can go up to 1000W, but during printing, it usually hovers between 100-120W

Depending on the country, electricity prices vary. For our example, let’s take $0.10 per kWh. With the settings we are going to print our Benchy it will take us about 40 minutes.

120 / 1000 * 0.67 * $0.10 = $0.008 (negligible)

Formula: Watts / 1000 * Time (hours) * Price per kWh = Costs for electricity for 3D print

Though this is not all…

You also have to recoup the money you have spent on buying the printer within a certain period - let's say 6 months (4392 hours) of printing. In our case, we are using Bambu Lab X1 Carbon, which costs about $1,200. This adds an additional fee of: $1,200 / 4392 * 0.67 = $0.18

Formula: Printer price / investment return time (hours) * print time (hours) = 3D printer operation costs

Rent and Software

This is not always applicable but should be taken into consideration. Right now, you may be printing out of the comfort of your house, but at some point, if you want to scale, you will need dedicated office space.

For our example, let’s keep it simple and not include costs for rent and software. Most 3D printing businesses that are just starting don’t have such expenses.

Combining all costs

Material costs: $29.99 / 1000 * 11.9 = $0.33

Labor costs: 5 / 60 * $14 = $1.17

3D printer operation costs: 120 / 1000 * 0.67 * $0.10 = $0.008 ; $1,200 / 4392 * 0.67 = $0.18

Rent and Software: N/A

Which all adds up to: $1.71

This is how much you need to sell a Benchy for if you want to keep a minimal profit. But is this how real businesses operate? Of course not…

That's why the next key factor comes in!

Margins for 3D printing

Knowing all the costs of operating a business and producing 3D prints is a good start, but that’s not enough to make it run profitably. More often than not, there are unexpected events that will eat into your profits if you don’t account for them. You need to add a certain percentage of margin that will cover printing accidents, extra maintenance costs, etc.

To do that, you need to have some past data about what percentage of prints fail. Setting a margin of about 30-40% of the material price should be a good start.

In our example: $0.33 * 35% = $0.12

Summing up costs and margin: $1.71 + $0.12

Additional costs for any 3D printing company

Costs and margins are the key things you have to keep in mind when creating your pricing strategy. But they are not all for sure.

You also need to consider the niche you are serving, the competition, the delivery period, etc.

Some niches are willing to pay higher prices (thus you can increase your margins) as not everyone can print exactly what they need as it may require some industry knowledge or specific filaments.

The other 3D printing businesses nearby are also a factor you have to keep an eye on, especially if you don’t have any competitive advantage outside of lower prices. Though, we highly recommend you stay away from that. You will be much better off if you try to differentiate yourself by adding additional services such as 3D scanning, making and editing 3D models, and post-production or just offering superb quality and guarantees.

Delivery periods can be tricky. Sometimes clients will want their order to be fulfilled as soon as possible and you can offer quicker delivery for a slightly increased price. But with bigger prints, try giving yourself at least a few days, so you know that even if the print fails, you will have time to start over and finish it on time.

Taxes on 3D printing businesses

We must also address the elephant in the room - taxes! You cannot have a legitimate business without being registered as a company and thus paying taxes.

All prices above are before tax. Adjust them according to the tax regulations of the country your business will be registered in.

Many beginners who are not paying taxes just yet make the mistake of not even considering them when creating their pricing strategy. They start giving quotes to customers for lower prices, which are unprofitable for a legitimate business. Clients will get used to them, and when you finally register your company, it will be very hard to convince past customers why you are increasing prices by 20% or more.

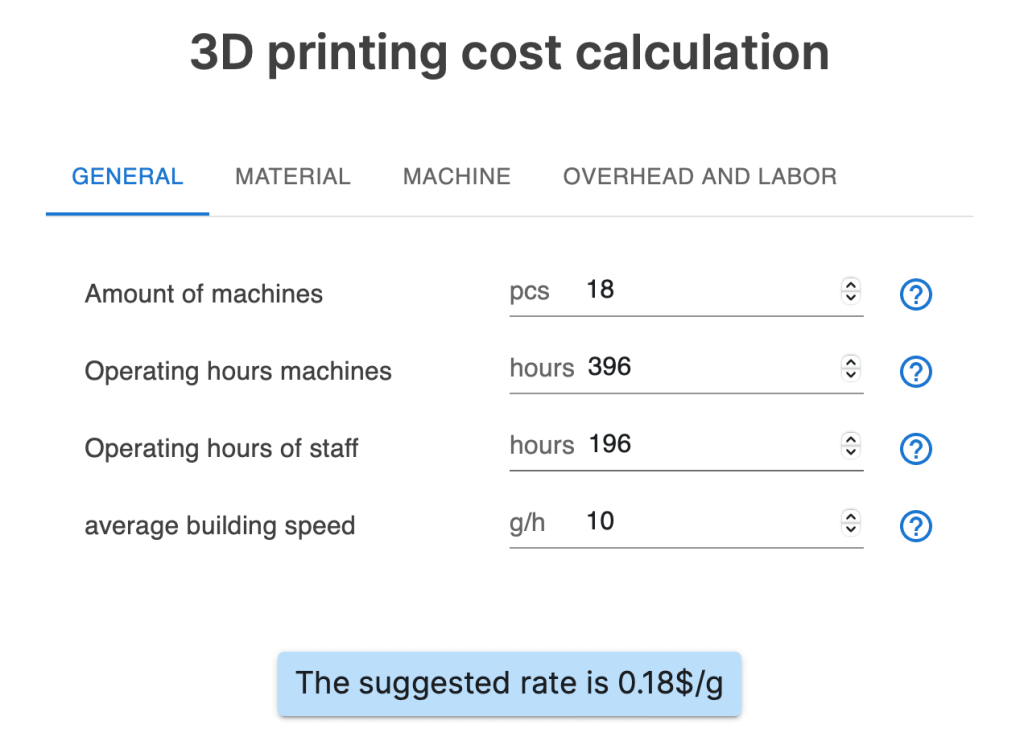

Calculate your 3D printing costs

In this guide, we covered a lot of stuff. For some people, it might be even a little overwhelming, we get it...

We have also made a rate calculator that makes things incredibly easy for you: just fill in the data, and it will give you the result immediately! 4 different tabs cover most of the variables in a business. With its help, you will be one step closer to a profitable 3D printing business!