How to calculate hourly machine rates

Hourly machining rates show the cost of operating a specific machine or cost center for one hour. These rates typically include not just the direct costs of running the machine, but also auxiliary costs and overhead costs. Most manufacturers aim to calculate an hourly rate that holds all related expenses, including anticipated costs like maintenance and repairs. That’s why most manufacturers need some years of data before having correct hourly rates.

If a client pays this calculated rate for each hour the machine is used, the machine owner will at least break even, ensuring the operation is sustainable.

Typical Industries that use it

- CNC milling

- Injection molding

- 3D printing

- Laser Engraving

- Laser Cutting

Components of Hourly Machining Rates

Several components contribute to calculating hourly machining rates, and the level of detail depends on how precise the manufacturer wants to be.

Fixed Costs

One of the most significant fixed costs directly tied to a machine,and often the highest, is depreciation. This is calculated based on the machine’s purchase price and its expected depreciation period. The method used can vary depending on how a company handles its accounting. Some businesses use fixed depreciation periods, such as 5 or 10 years, while others base it on the average lifespan of the specific machine.

Depreciation costs can be substantial, especially for manufacturers that rely on high-end or specialized equipment. Accurately accounting for this expense is critical to ensure that hourly rates reflect the true cost of owning and operating the machine.

Variable Costs

There’s a lot that can fall into this category, but to keep things straightforward, consider all the operating costs directly related to running the machine.

For simplicity, many companies calculate operating costs for specific machine groups rather than individual machines. For instance, with CNC milling machines, you’d group costs like electricity, water, maintenance, repairs, oil, and cutting tools. Combining these costs provides an average operating expense for that machine group.

However, larger companies with advanced ERP systems may take a more granular approach, attributing operating costs to individual machines. The level of detail ultimately depends on how precise the manufacturer wants their calculations to be. The higher the volume of production is, the more important it gets to have this detailed, as the profit margins usually become thinner.

Labor Costs

Labor is a critical factor, particularly in countries with high labor costs. If staff members such as technicians, programmers, or operators are directly involved in running the machine, their wages must be included in the hourly rate. Labor costs can represent a significant portion of total expenses, and overlooking them would lead to inaccurate rates. It’s essential to account for this to ensure the sustainability and profitability of your operations.

Overhead Costs

Rent, administrative expenses, and other costs, such as software licenses, should also be factored into your machine rates. These costs need to be accounted for somewhere, so it’s important to include them in your calculations.

To allocate these expenses across machines or cost centers, you can use logical methods. For example, rent can be divided based on the square meters occupied by each cost center. Similarly, overhead costs like accounting, purchasing, HR, and project management can be distributed evenly across all machines.

The key is to ensure every expense is captured and appropriately allocated, so nothing is left out of the hourly rate calculation.

Step-by-Step Process to Calculate Hourly Machining Rates

Let’s walk through a step-by-step guide for calculating hourly machining rates using the calculator provided by Quoter.ai. The process is straightforward and similar to what you might find on various business or manufacturing websites.

Take, for example, a small 3D print shop. This shop has 18 machines, all FDM printers. The owner has just completed the first year of operations but noticed the financial results don’t match his expectations.

Now it’s time to crunch the numbers and determine a good hourly rate for his services.

On average, each machine operates for around 396 hours per month. The owner and his only employee together spend approximately 196 hours per month on tasks such as operating the printers, removing prints, and dealing with support structures.

By breaking down the costs step by step, the owner can pinpoint an appropriate hourly rate that covers expenses and ensures profitability. Let’s continue to calculate the specific numbers.

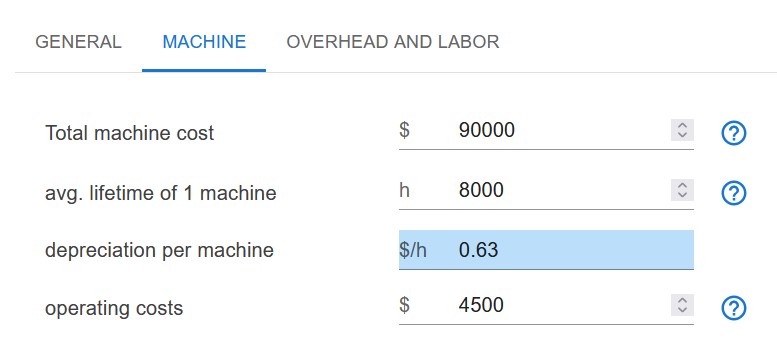

The 18 machines in the print shop were purchased for a total of $90,000. According to the manufacturer, these machines have an estimated lifetime of 8,000 hours each.

To calculate depreciation, divide the total cost of the machines by their expected lifetime:

Depreciation per hour = $90,000 ÷ (18 machines × 8,000 hours) = $0.625/hour per machine.

In addition to depreciation, the owner incurred $4,500 in operating costs over the past year. This includes expenses such as electricity, maintenance, and consumables. These costs need to be factored into the hourly rate as well to ensure all operational expenses are covered.

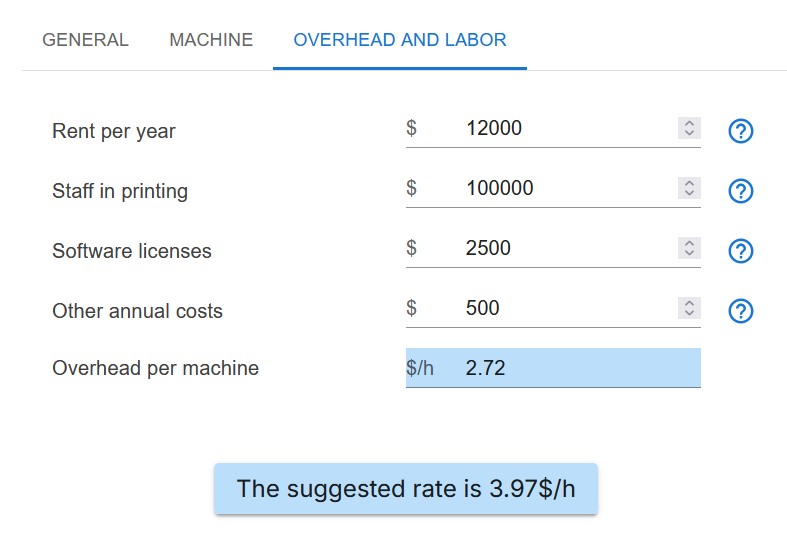

Next, the owner factors in labor costs, rent, and additional expenses to calculate the total operating cost.

The combined annual salary for the owner and his partner is $100,000. Their annual rent goes for $12,000. Then there are software licenses for design software that needs to be paid once a year of $2,500.

And lastly, another $500 that sums up other costs that do not have a fixed department or cause linked to it.

After inputting all the numbers into the calculator, the owner finds out that the appropriate base hourly rate for his FDM printing service is $4 per hour. This covers all operational costs, including depreciation, labor, rent, and miscellaneous expenses, ensuring the business breaks even.

Now, breaking even is good, profit is better. The owner decides to add a small profit margin and sets his final rate at $5 per hour.

By using this calculated approach, the owner can confidently price his services, knowing that all costs are accounted for and the business remains sustainable.

Common Mistakes when calculating the hourly rate

The biggest mistake when calculating hourly machining rates is failing to include all the costs that actually occur. Many manufacturers set their rates too low, often overlooking critical expenses such as overhead, labor, maintenance, or repair costs. This oversight can lead to under pricing and, ultimately, unprofitable operations.

If you're just starting your business, it’s understandable that you might not yet have a complete picture of your operating costs. However, this makes it even more important to regularly revisit and update your calculations. As costs for things like electricity, labor, and materials change over time, you should make it a habit to recalculate your hourly rates at least once a year.

A good rule of thumb is to take the time to review your rates when analyzing your annual financial performance. Double-checking ensures your rates remain accurate and reflective of your true costs.

Other common pitfalls to avoid include:

- Ignoring downtime and machine inefficiencies.

- Underestimating tooling wear and maintenance costs.

- Failing to account for shifts in labor costs or fluctuating electricity rates.

Where to apply the hourly machine rate

Hourly machine rates are essential in many areas, not just for gaining insights into production and profitability but also for planning and decision-making at every stage of operations. To understand their full importance, let’s start at the very beginning—before the machines even start running.

Cost calculation for new projects

Most manufacturers rely on the hourly rate as a key component of their quotation process. In fact, it’s often the main area where they can apply a margin to generate profit. With today’s increasing price transparency, simply adding a markup to sourced materials is no longer enough. Real value comes from the manufacturer’s expertise, skills, and the effective use of their machines. Those who have dealt with the automotive industry, especially with large OEMs know exactly to what extent price transparency is required.

To create a professional and competitive quote, the numbers must be realistic. If the rate is set too low, the manufacturer risks losing money—no client will remind you to adjust an under priced quote. On the other hand, if the rate is too high, you may lose the prospect entirely, or worse, leave them feeling undervalued or disrespected. Striking the right balance is critical for maintaining both profitability and client relationships.

Profitability analysis

One of the most common uses of hourly machining rates is to analyze the costs of completed projects in a machine shop. Every business tracks the machining hours required for a product or project. Then applying the machine’s hourly rate to calculate the total cost is a straightforward thing to do. From there, it's a simple step to compare this cost with the purchase order value received from the customer.

This type of post-project calculation is a routine exercise that the management in almost every manufacturing company will require. It often plays into KPIs as well.

Cost Optimization

While the pricing of materials and purchased goods is usually straightforward, manufacturing is often where inefficiencies start. Understanding where money is spent—or lost—during the production process is essential. This insight allows manufacturers to identify areas that need further investigation, whether that means investing in new equipment, improving workflows, or providing additional training to employees. You always need data to make good decisions, especially with the high level of competition in today’s world.

Moreover, knowing these details enables businesses to benchmark their performance against competitors, ensuring they stay competitive in the industry.