Top 5 Trends in Additive Manufacturing for 2025

Additive manufacturing, often called 3D printing, isn’t necessarily a new trend in the manufacturing industry. It has been around for a while, but did not find widespread adaptation.

With the offering of consumer grade 3D desktop printers, for affordable prices, the speed of innovation in this niche has exploded.Not only did the technology improve and get cheaper, it also captured many innovative minds and started to create huge communities of experts.

There are several topics and problems that additive manufacturing has on its plate to solve in the following years.

What are some of the adaptations that we are seeing in the manufacturing and service industry? Staying up to date with new trends is important, they often provide great business opportunities

Trend 1: Advancements in material science

Most users of additive manufacturing are well versed with PLA, ABS and maybe occasionally Nylon. However, over the last years the research into new materials, such as composites, biocompatible materials and fully recyclable materials has brought new choices.

Aerospace

The main requirements for materials in the aerospace sector are lightweight, high-strength and flame retardant material.

There is a good reason why Aerospace and additive manufacturing belong together, the low quantity of needed parts.

Think about it, how many airplanes can Airbus build in a year? If we take toilet seats as an example (they are made out of Ultem), then we are talking about quantities <2000pcs per year.With quantities like this, it is often worth it to just print those in order to save costs on tooling.

Some of the most common materials that are now available in additive manufacturing for aerospace are:

PEEK

It stands for Polyetheretherketone and is a semi-crystalline thermoplastic. It stands out in its stability, flame-retardant properties, chemical resistance and mechanical strength.

Common applications are cable insulations, seals and interior components.

PEI (Ultem)

This is another commonly used material in aerospace. Nearly all interior that you can see as a passenger is made with PEI (Ultem). It is expensive and cannot even be compared with regular plastic materials, in terms of price. However, there are brands such as Stratasys that offer certified Ultem material for FDM printers. Those printed parts are in fact used in aerospace today.

Inconel (Inconel 718)

It is a nickel-chromium alloy and has great corrosion resistance, strength and is suitable for high temperatures. This suits Inconel for extreme environments, like as a component in the combustion of jet engines. Turbine blades are one of the use cases.

Healthcare

Additive manufacturing is huge in healthcare and the growth isn’t slowing down at all.

This is worth a whole article by itself. The main properties that impact its application in healthcare are the biocompatibility, sterilizability and of course some mechanical properties.

PLA

This material does not need much introduction, it is often the first touchpoint when dealing with 3D printing. Every additive manufacturing enthusiast knows this material well.

It is mainly used due to its biodegradable properties and that it is derived from renewable resources like corn starch.

It’s usually used for prototyping of medical devices, dental guides and models that are used for education and studies.

Titanium

This one is biocompatible, strong and easily integrated with human tissue. It is commonly used for implants, like knee and hip replacements. Another very common use is in the dental industry as implants. It has become a widely adopted service that dentists use, in order to provide custom dental implants. This is also one of the business areas that is growing a lot and highly lucrative, with a slightly higher barrier to entry.

Silicone

This material itself, not just related to additive manufacturing, is taking market share for many years. While there are different grades, we are talking about the medical grade. It is flexible, biocompatible and can be sterilized with ease. The flexibility allows the use for soft tissue applications such as custom fit implants and facial prosthetics. It keeps growing and gaining experience working with this material has huge upsides.

Trend 2: AI-Driven Optimization in 3D Printing

AI technology is nowadays used in almost every business field, additive manufacturing is not shy of it either. The use of AI optimizes various printing parameters. So instead of relying on the human input when slicing a model and setting the printing parameters, there are AI algorithms that figure out the most efficient settings. Potential failures can be predicted and adjustments are made before the print has even started.

Overall, the quality and speed is increased, which is essential for turning a profit on printing operations.

AI-Assisted Generative Design

The overall designing process is still mostly done by humans. However, there are many features within a design that can be optimized and has to be automated. It would take designers way too much time and effort. A good example is the structure of an object in order to reduce material waste and still retain the required strength.

This is a job that requires loads of computing power and an AI that can immediately simulate changes according to strength, weight and other factors.

Some of the larger design software companies are experimenting with those features. It can be expected to grow and eventually hit the retail users as well.

Quality Control in Real-time

Taking in data from sensors and cameras that monitor the print, helps in early detection of defects or deviations. There are already a few solutions on the market that are dealing with this system. It is incredibly useful to have an AI algorithm evaluate all printing parameters in real-time, then give an alarm if needed.

You, as a manufacturer, need this information as early as possible in order to save time and costs on parts that would eventually fail the QC test.

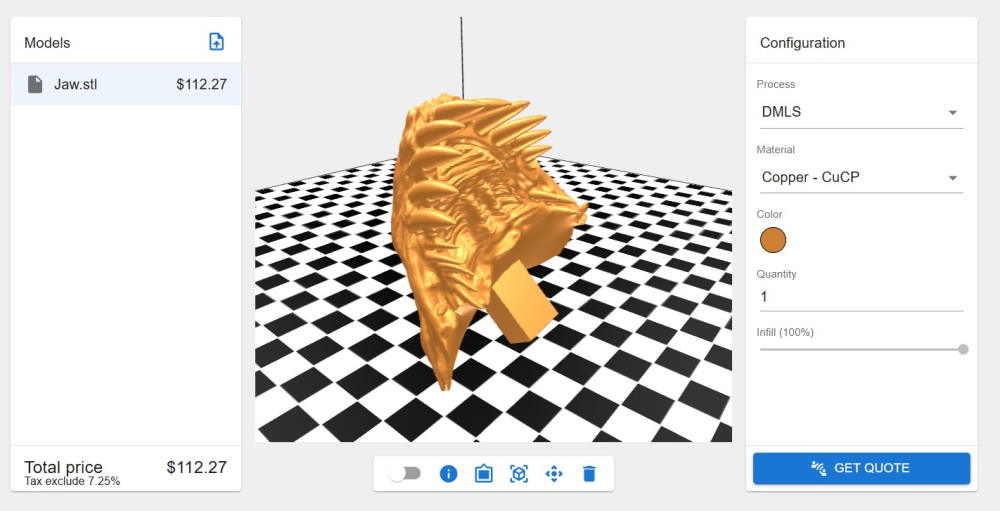

Automated Print time estimation

Currently, most manufacturers are manually taking input from a prospect and running it through their slicers, in order to figure out the print time and related costs.

This not only takes plenty of valuable time from the engineer, but it also reduces the chances of getting the order. Most customers will place the order to the first shop that was able to give them a (realistic) quote.

Automated quotation systems that utilize slicing, orientation tools and machine learning can give those companies an edge in this competitive market.

Trend 4: Expansion of Metal 3D Printing

Metal additive manufacturing has been around for some time. There are various ways of doing so, SLM/SLS and binder jetting are probably the two most common techniques. Here I want to emphasize on SLM and SLS, as those processes can achieve steel quality and integrity that are on par with regular steel.

Being able to print steel at the same quality level as manufacturing it through subtractive processes is huge for several industries.

Aerospace & Medical Sector

As briefly discussed in the previous chapter, there are already several use cases for steel prints in those industries. They mainly go from prototypes to small production runs in order to save costs or to create very complex shapes with ease.

Especially when it comes to custom parts that are tailored to the anatomy of each patient, this technology shines.

Automotive Industry

The prototyping and boutique performance tuning industry is being revolutionized through steel additive manufacturing innovation. It allows manufacturers to be more flexible with their design ideas and create lightweight solutions that are still as strong as needed.

The impact on vehicle performance and fuel efficiency is huge. Some examples are engine brackets, heat exchanges and transmission components that are produced in aluminum and stainless steel.

It is to note, that all of this is just applicable to low production volumes, as steel additive manufacturing is not yet on a level for efficient production of larger quantities.

Plastic injection industry

One of the largest industries that most people are not aware of, is the plastic manufacturing industry, in particular plastic injection.

Most of the OEMs that you will interact with on a daily basis, are purchasing their plastic components from plastic manufacturing suppliers.

The process is quite complex, but to break it down:

- Make a mold out of steel, to form the plastic part

- Put the mold in a machine and injection molten plastic in there

- Let it cool down and then eject the plastic part

It all comes down to how many parts can you produce in one cycle and how long is the cycle. This can make cost differences of 5-6 digits per year, if done correctly.

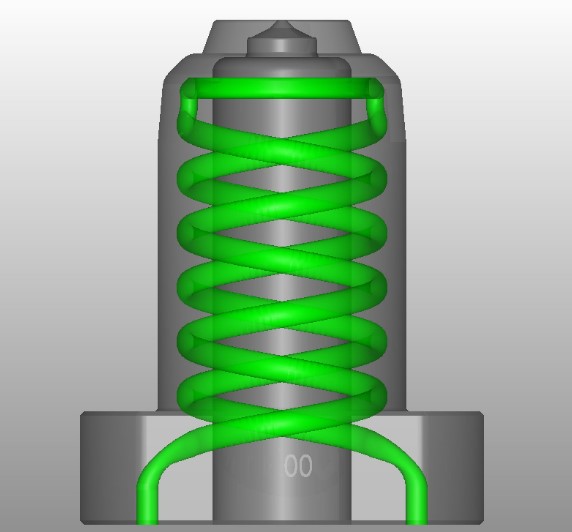

The cooling time takes up 30-50% of the cycle time and is often non-negotiable, as the plastic has to cool down. There are water channels that help to cool it down, but due to the geometry of drills, they are often quite far from the plastic surface.

With 3D printed inserts, it is possible to print in cooling channels that are conformal with the plastic surface and therefore provide a much stronger cooling effect.

This allows to reduce the cycle time by 10-30%, depending on the project.

Trend 5: Focus on Sustainability and Circular Manufacturing

With a trend to more sustainability, additive manufacturing is in the right spot. As the name suggests, it is additive, so there is only little scrap. This becomes very obvious when comparing it to subtractive methods, such as CNC machining, which have lots of scrap.

Closed-loop recycling

A good example is the typical SLS/SLM printer. They work with steel/titanium/aluminum powders and use a laser to melt it together. Any of the material that isn’t used to produce the finished print, is automatically recycled and can be reused for the next print. This minimizes waste and keeps the production more sustainable and cheaper.

Bio-based materials

PLAs are a good example for biodegradable materials that come from renewable resources. They keep gaining traction compared to traditional plastics, due to their sustainability. There is less environmental long-term impact, because the materials break down more easily.

Energy-efficiency in new printer designs

The technology and design of printers keeps improving. One of the most valuable innovations is to lower the energy consumption of additive manufacturing. Improved design of heating elements, better motion control and less idle times make those systems more sustainable.

Next to the innovations in hardware, the AI-assisted design tools & path generations should be mentioned here as well. It lowers the overall printing time and reduces material consumption.

This is incredibly important, to get the prices of higher quantity printing projects down.

Takeaway for what’s coming in 2025

Innovation is again accelerating, after the covid slump. Almost constantly new hardware & software tweaks come up and improve the business of additive manufacturing. For anyone reading this article, there is only one important point that you need to get straight.

If you want to succeed in this new business sector, you have to stay updated. Additive manufacturing keeps improving and relying on old technology will make your business unprofitable. Even though it seems that 3D printing has reached a large audience, we are still in the beginning of utilizing this technology for manufacturing applications, especially when talking about higher quantities.

Stay ahead of your competition. I recommend subscribing to newsletters of larger manufacturers such as Stratasys, MakerBot, Arburg and additive manufacturing communities. This helps to stay up-to-date and exchange ideas with enthusiasts and professionals.