Popular 3D Printing Materials

Which material should I choose for my project?

3D printing technology allows individuals and companies to quickly and cost-effectively produce prototypes and proof of concepts. Due to its technology, there are few limitations to what can be printed, in terms of design. In case mass production will be the next step it does make sense to talk with injection molders about manufacturability.

Another big question that often comes up is material selection. There are plenty of materials and it isn't as easy as it sounds to choose one. Generally, the best advice here is simply to use the material sufficient for the application.

- Use a material that comes close to the material that is supposed to be used for mass production

- If you are unsure, try to find out what capabilities your material should have

- Strength and durability?

- Flexibility

- Cosmetics? Transparency?

- Environment to be used, humid or dry?

- Does it need chemical resistance?

- What surrounding temperatures will the part be exposed to?

- Last but not least, what is your budget, and do you know a shop that has the technology and material that you want

To make the decision a little bit easier, have a look at the popular materials below. Generally said, for anything that does not require specific technical capabilities and is rather decorative, it is recommended to use PLA or PETG, as those are inexpensive and easily available.

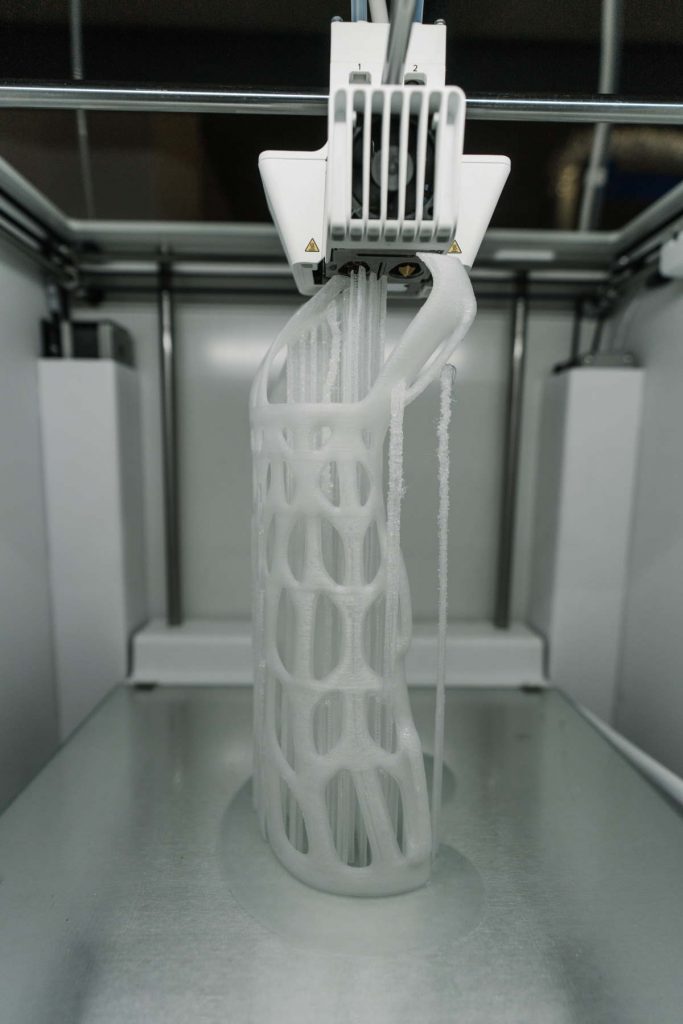

FDM Printing

FDM, which stands for Fused Deposition Modeling has become the most commonly used 3D printing process, be it for home projects or industrial prototyping. The layer-by-layer deposition needs filament to build the desired object. Nowadays there is a filament of almost every plastic material available, including some high-end engineering plastics like ULTEM. Let's take a plunge into the most popular materials:

| Material | Features |

|---|---|

| ABS (Acrylonitrile butadiene styrene) | Durable & Tough High impact resistance High heat resistance |

| PLA (Polylactic Acid) | Stiff & good strength, but can get brittle Low heat resistance Low UV resistance |

| PET (Polyethylene terephthalate) | Glossy and smooth surface Transparency Humidity and chemical resistant |

| NYLON (PA -> Polyamides) | Tough and flexible High impact resistance Low humidity resistance |

| TPU (Thermoplastic polyurethane) | Flexible and stretchable High impact resistance Rubber-like |

| Composites (Talc, fiberglass, carbon fiber) | High impact resistance High strength and toughness |

SLA Printing

SLA, Stereolithography, is quite different from FDM and has its own advantages. The material being used comes in form of liquid resin, which is hardened by a UV laser. This means that only photopolymer resins can be used. Luckily, there are enough material variations in the market.

| Material | Features |

|---|---|

| PC-like Resins | High-temperature resistance High strength Can be translucent |

| ABS-like Resins | High strength Durable Enough flexibility to offer snap-fit |

| PP-like Resins | Excellent resolution and details Most flexible SLA material |

Metal 3D Printing

There are several processes that can print metal, such as SLM, DMLS, and SLS. Metal printing has revolutionized serval industries, such as dental, aerospace & prototyping. The variation of metal is high, in all those mentioned processes, the metal material comes in form of powder.

| Material | Features |

|---|---|

| Stainless steel | high corrosion resistance high strength easy to maintain |

| Tool steel | heat resistance high strength high hardness |

| Titanium | lightweight high strength high corrosion resistance |

| Copper | thermal and electrical conductivity |

| Aluminum | high strength lightweight chemical resistance |