What do you need to start a 3D printing business?

The world of 3D printing has become a booming industry in recent years, with endless opportunities for entrepreneurs to start their own profitable businesses. You can turn your passion for 3D printing into a lucrative business venture with the right skills, equipment, and materials. However, starting a 3D printing business requires a comprehensive understanding of the industry and the necessary tools for success.

In this post, we will discuss the key points to consider when starting a profitable 3D printing business, including essential skills and knowledge, choosing a niche, equipment, costs, printing space, streamlining the process, pricing, and profitability. Whether you are just starting or looking to expand your existing business, this guide will provide the necessary information to start and maintain a successful 3D printing business.

3D Printing Skills & Knowledge

Starting a 3D printing business is like any other business - it requires a certain level of expertise in the field. While you don't need a degree in engineering or industrial design to start a successful 3D printing business, you do need to have some knowledge and skills. The more essential ones include:

Understanding of the 3D printing technology

Having a good understanding of 3D printing technology is essential when starting a 3D printing business. 3D printing is a rapidly evolving technology that has the potential to revolutionize the manufacturing industry. Understanding the principles behind 3D printing, its benefits, and its limitations will give you the knowledge and confidence to make informed decisions about your business.

When you are deciding what printers to buy, you need to understand the different 3D printing technologies available, such as Fused Deposition Modeling (FDM), Stereolithography (SLA), and Selective Laser Sintering (SLS). Each technology has its own strengths and limitations, and understanding these can help you make an informed decision about what type of printer is right for your business. For example, FDM printers are generally more affordable and easy to use, while SLA printers can produce higher-resolution prints but are more expensive.

Additionally, understanding 3D printing technology is critical when choosing a niche for your business. You need to consider what products you want to produce and whether 3D printing is the right technology for your chosen niche. For example, if you are interested in producing medical devices, you need to understand the regulations around medical devices and how 3D printing can be used to create them. Having a good understanding of 3D printing technology will help you identify the niches that are best suited to your skills and interests.

Technical Skills

Technical skills are essential in ensuring that your 3D printing operation runs smoothly. Knowing how to troubleshoot common issues and fix technical problems that may arise will save you time and money in the long run. This will help minimize downtime and increase productivity, which is critical in a competitive business environment.

Furthermore, having technical expertise and knowledge of the 3D printing process will help you optimize your workflow and streamline your production process. This includes setting up and maintaining your 3D printers, preparing files for printing, and ensuring that your products meet quality standards. By mastering these technical skills, you can improve your efficiency, reduce waste, and increase your bottom line.

Material Knowledge

In the world of 3D printing, choosing the right material for a project is crucial. With a vast range of materials available understanding their properties and applications is paramount.

Having a good understanding of material knowledge means knowing the difference between materials in terms of strength, flexibility, heat resistance, and durability. This knowledge will help you to determine which material is best suited for your particular project. For example, if you are creating a functional part that requires high strength and rigidity, you may choose a material like carbon fiber-reinforced nylon. On the other hand, if you are creating home decoration, PLA will most likely suffice.

Understanding 3D printing materials also includes being aware of their limitations. Some materials may be more prone to warping, shrinking, or cracking during the printing process, while others may require special handling or post-processing. By being aware of these limitations, you can avoid costly mistakes and ensure that your prints come out as intended. Additionally, it is important to stay up-to-date with new materials that become available on the market, as they may provide new opportunities for your business or improve the quality of your prints.

Moreover, material costs can quickly add up, especially if you are producing large quantities of prints. By having a good understanding of the materials, you can make informed decisions on what materials to purchase and avoid overpaying for materials that may not be the best fit for your projects. This knowledge can help you to save money and increase your profitability.

Business Skills

Running a successful 3D printing business requires more than just technical skills and an understanding of the technology. You also need to have some basic business skills, such as budgeting, marketing, and sales. With these skills, you can start and run your 3D printing business effectively and profitably.

Budgeting is an essential business skill that will help you manage your finances and make sure that you have enough funds to cover your expenses. You will need to create a budget that includes all of your costs, such as equipment, materials, rent, and marketing. By doing so, you can ensure that you have enough money to cover your expenses and invest in your business.

Marketing is another important business skill that will help you promote your business and attract customers. You need to be able to identify your target market, create a marketing strategy, and execute it effectively. This includes identifying your unique selling points, creating compelling content, and leveraging social media and other digital marketing channels to reach your audience.

Sales skills are also crucial for running a successful 3D printing business. You need to be able to communicate effectively with potential customers, understand their needs and requirements, and offer them solutions that meet their needs. You should also be able to negotiate prices and close deals effectively to grow your business and increase your profits.

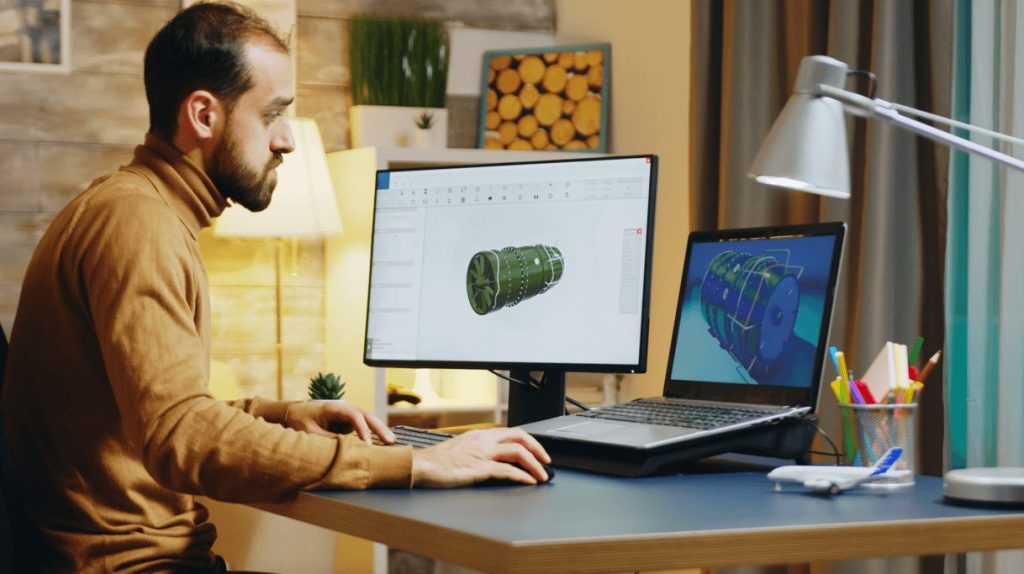

3D Modeling

In a 3D printing business, 3D modeling is an essential skill that allows you to create and modify digital 3D models that can be printed in three dimensions. Being proficient with 3D design software will enable you to create 3D models from scratch or modify existing models to suit your client's needs.

If you aren’t proficient in 3D modeling yourself, you can also hire a 3D designer to create 3D models for your clients. Regardless of the approach you choose, being able to offer 3D modeling as an additional service can be an advantage over the competition.

By acquiring the necessary skills and knowledge, you will be able to produce high-quality 3D prints and provide value-added services to your clients. Moreover, a solid foundation in these areas will help you run your business more efficiently and effectively.

Equipment for your printing business

To start a 3D printing business, you will need to invest in equipment that meets your business needs. The equipment required will depend on the type of 3D printing projects you plan to undertake, the volume of work, and the materials you plan to use.

The two primary types of 3D printers are Fused Deposition Modelling (FDM) and Stereolithography (SLA). FDM printers are more affordable and suitable for printing larger objects using plastics, while SLA printers are more expensive and can produce higher-resolution prints using photopolymer resins. The type of printer you will need greatly depends on the niche you are going to choose, as SLA printers have much more limited applications.

When purchasing a 3D printer, it is essential to consider factors such as cost, quality, reliability, and support. You should also consider the manufacturer's warranty, availability of replacement parts, and ease of use.

In addition to 3D printers, it’s also a good idea to invest in a 3D scanner. It allows you to capture the geometry of real-world objects and create 3D models. This can be very useful in certain niches where you will be working with real-life parts.

Post-processing equipment won’t cost you much and you can pretty much get it without a need for thorough research, unlike a 3D printer and 3D scanner. If you don’t offer such services, having some sandpaper laying around can be very useful to deal with little imperfections.

Choosing a 3D Printing Niche

Choosing a niche is crucial for the success of your 3D printing business. A niche is a specific area of expertise or specialization that distinguishes your business from others in the market. By choosing a niche, you can tailor your services to meet the needs of a specific group of customers and differentiate yourself from competitors.

Some examples of niches in the 3D printing industry include:

- Prototyping: Providing rapid prototyping services to engineering and manufacturing companies.

- Architecture and construction: Using 3D printing technology to create building models, interior designs, and architectural models.

- Jewelry: Creating customized and personalized jewelry using 3D printing technology.

- Medical: Creating prosthetics, implants, and other medical devices using 3D printing technology.

- Replacement parts: 3D printing can be used to create replacement parts for products that are no longer available or difficult to source.

- Customization: Creating customized products tailored to the individual needs of your clients.

When choosing a niche, it is important to consider factors such as market demand, competition, and profitability. You should also consider your interests, skills, and resources to ensure you can provide high-quality services in your chosen niche. By selecting a niche that aligns with your strengths and interests, you can differentiate yourself from competitors, offer superb service, and establish a strong brand identity.

Pricing and Profitability

Setting the right price for your 3D printing services is crucial to the success of your business. You want to make sure you are charging enough to cover your costs and make a profit, but not so much that potential clients are deterred.

To set the right price for your 3D printing services, you need to take into consideration the costs involved in each project, including the cost of materials, equipment, and labor. You also need to consider the level of expertise required for the project and the competition in the market.

Once you have determined the costs involved, you can add a profit margin to arrive at the final price. The profit margin will depend on the level of competition in the market and the quality of your work. It is essential to research the market to determine what your competitors are charging and what their quality of work is like.

To ensure that you do not lose money on a project, it is important to factor in the cost of mistakes and unexpected expenses. You can do this by adding a buffer to the final price to account for any unforeseen costs.

We have created a great tool that can help you calculate what you should charge for your services. You can check it out here.

Streamlining the Process

Streamlining the 3D printing process is essential to ensure your business operates efficiently. This involves optimizing the workflow from 3D modeling to finished product delivery.

One way to streamline the 3D printing process is to standardize your workflow. This involves creating a step-by-step process for every project and adhering to it consistently. By standardizing your workflow, you can reduce errors and minimize the time taken to complete each project.

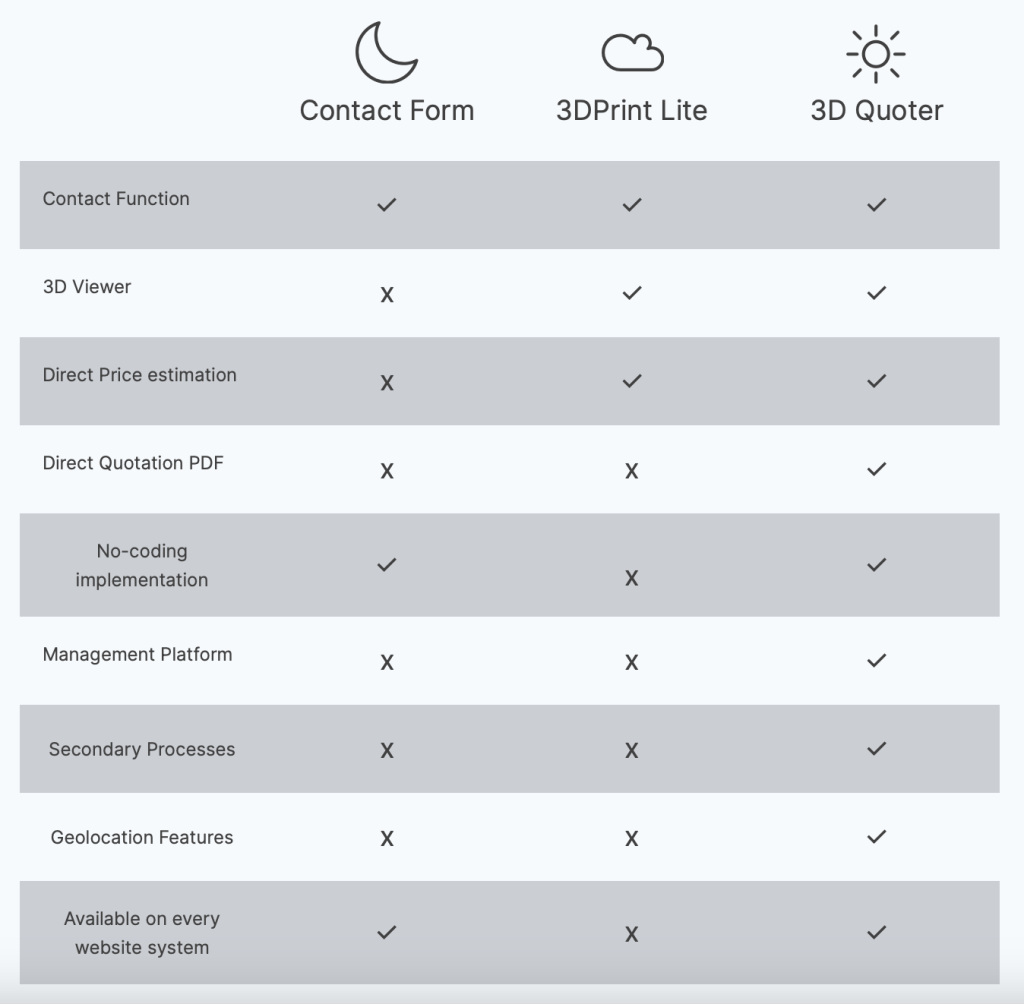

Another way to streamline the 3D printing process is to use automation tools. Automation tools can help automate certain aspects of the 3D printing business, such as giving customers quotes. This greatly reduces the time you will spend talking with customers so that you can focus on your craft.

Want to try an automation tool but don’t know where to start? Quoter.ai might be the right one for you. It offers all the best features on the market and some additional ones! With it, you are getting a 3D viewer, direct price estimation, direct quotation PDF, no-coding implementation, and much more.

Rough Costs to Start a 3D Printing Business

Starting a 3D printing business involves upfront costs. They will depend on several factors, including the type of 3D printing projects you plan to undertake, the equipment you need, and the location of your business. Here are some of the expenses to consider:

- 3D printers: This is your main upfront cost. The good thing is that you can get only one printer when starting out. Then as the projects pile up, you can think about getting more printers. The cost of 3D printers can vary widely, depending on the type and brand you choose. Entry-level FDM printers can cost as little as a few hundred dollars, while high-end SLA printers can cost tens of thousands of dollars.

- Equipment and accessories: In addition to 3D printers, you might also need to purchase other equipment and accessories such as a computer, 3D scanner, and post-processing equipment. The cost of these items can range from a few hundred dollars to several thousand dollars.

- Materials: Get the basic colors and most widely used materials first. The cost of 3D printing materials can vary depending on the type of material you use and the volume you order.

- Space: Hopefully, you already have a space where you can set up your 3D printers but if you don’t you might need a dedicated space to set up your 3D printing business. The cost of renting or purchasing a workspace will depend on the location and size of the space.

- Business expenses: You will also need to consider other business expenses such as permits, insurance, marketing, utilities, etc.

- Education: Having a successful business in a such fast-paced environment like 3D printing means always staying on top of trends and the latest developments. Usually, the information can be acquired for free online, but sometimes it might be a good idea to get a paid course.

Overall, the cost of starting a 3D printing business can range from a few hundred dollars to tens of thousands of dollars, depending on your specific requirements. It's important to create a business plan and go into more detail about the numbers of the business. Calculate your expected expenses and potential income and see how long will it take to break even. If you are unsure about making a big investment in the beginning, you can always start small with a 3D printer, a few rolls of filament, and a willingness to deliver a great service!

Should I start a 3D printing business?

Starting a 3D printing business can be a lucrative and rewarding venture. However, it requires careful planning, knowledge of the industry, and a passion for the technology.

To start a profitable 3D printing business, you need to have the right skills, knowledge, and equipment. You also need to choose a niche that aligns with your interests and expertise. Investing in the right equipment and creating a workspace that suits your needs is also essential.

Moreover, you should focus on streamlining your workflow, investing in training and development, and setting the right price to ensure your business operates efficiently and effectively while maintaining profitability.

By following these key steps and staying up-to-date with the latest trends and technologies in the 3D printing industry, you can create a successful and thriving 3D printing business that stands out from the competition.

So, if you're thinking of starting a 3D printing business, don't hesitate to take the leap and turn your passion into a profitable business venture. Good luck!